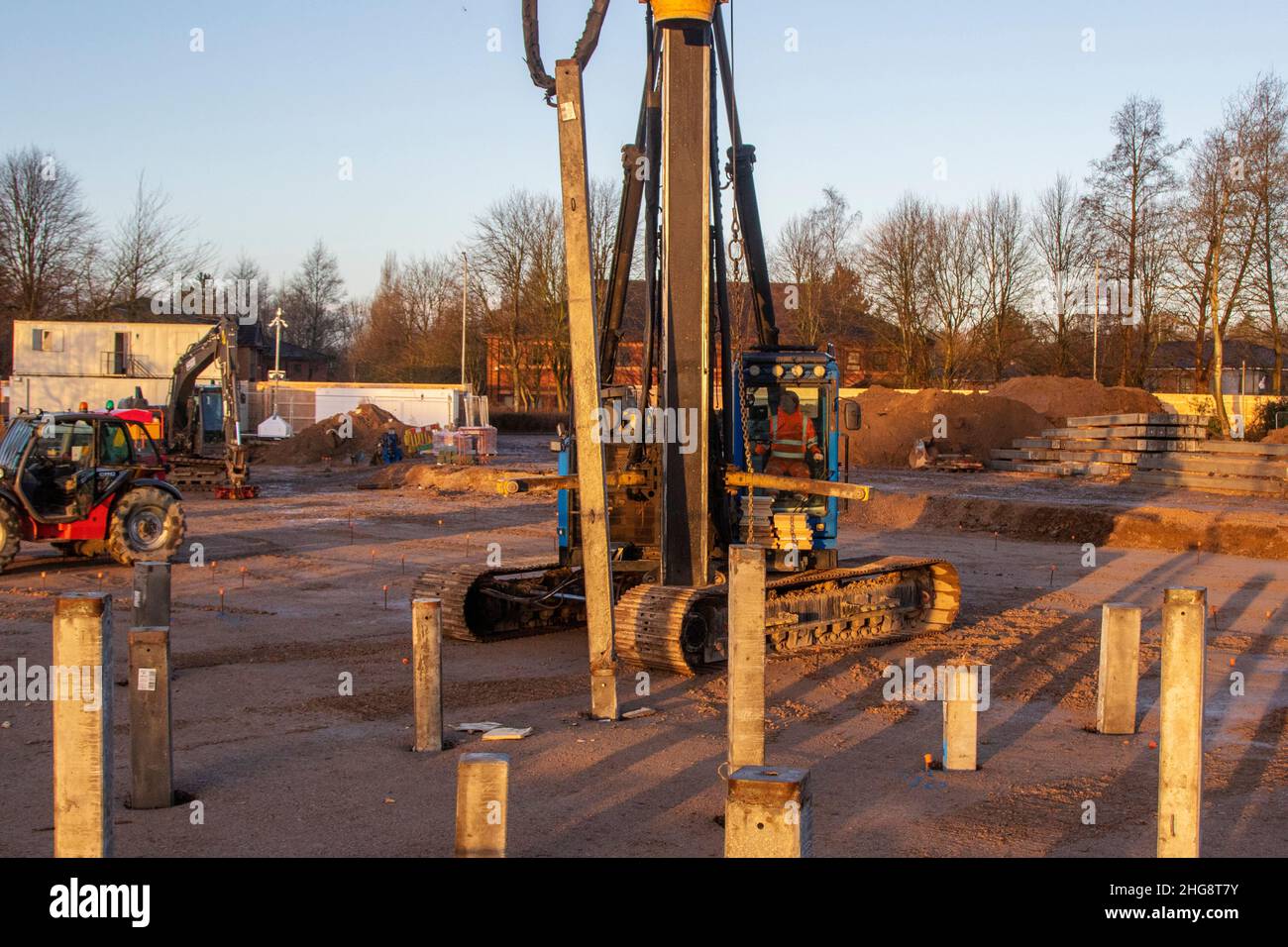

Pre-cast stacks are set up by driving while cast-in-situ heap is created by boring a hole followed by placing fresh flynn piling north west concrete. Concrete heaps are used as foundation components that sustains mostly all types of frameworks specifically in areas where deterioration is specific or highly prepared for. Solid concrete piles are commonly circular and also rectangular in random sample. Hollow concrete stacks or rotated stacks has form like a doughnut with thinner wall surfaces. Sectional Flight Auger piling-- this strategy is made use of where there is reduced head space or on really limited work websites where you are unable to utilize a bigger CFA rig.

What is a mini-pile vs stack?

Mini loading is a kind of loading that has a smaller sized diameter than common stacking. Consequently, they are light and inexpensive while still having the ability to hold up against high weights. One of https://troyicix059.weebly.com/blog/what-are-the-merits-and-drawbacks-of-socketted-h-pile-over-mini-pile the most usual sort of little loading is a hollow steel shaft attached or drilled right into the ground.

For websites that have much more homogenous dirt accounts, other structures such as auger cast heaps or driven stacks are favored. Micropile is very strong, high-capacity drilled deep foundation components that have the capability to support loads above 200 lots at depths above 200 feet. High-strength steel utilizes for Micropile construction in addition to steel casings, rebar, and also cement. A framework's foundation moves its tons to a layer of dirt or rock that can support its weight without negotiation issues. These structures are normally composed of long, slim columns of steel, enhanced concrete, or hardwood. Piled structures are specified as having a deepness going beyond 3 times their breadth.

Just How Driven Heaps Function

As a result of the steel housing, the Franki pile can be installed in the visibility of superficial water table. A steel case is initial pressed right into the soil to the called for deepness. This technique involves presenting pressurised water to the soil after that the water-soil blend is literally drawn out of the case. Therefore, it can frequently be tough to achieve the wanted up-lift capacity from a driven stack as the installation approach can avoid further embedment from being achieved. The means they work from a Structural Design viewpoint is really similar. A typical piling option can confirm tough in a minimal access area as well as depending on the plan, a center's procedures can be interrupted or outright stopped throughout installment.

ESC is a premium provider as well as installer of imported as well as domestically made steel pipeline piles, sheet piles, combi-walls, structural steel, and also other loading solutions. Please do not think twice to call us at for your particular enquiries or concern. Driven piles are additionally called 'variation' piles because the setup process displaces an amount of dirt matching to the quantity of the driven heap. H-section steel or steel pipe at the bottom and also concrete pile at the top. This takes place in scenarios where the required pile size for appropriate anchorage is longer than the lengthiest possible cast-in-situ stack. As a remedy, a steel stack can be driven initially to the wanted strata then proceed with a cast-in-situ burnt out stack.

Benefits Of Piling As Well As Mini-piling

A centraliser is utilized for positioning the rebar cage inside the birthed. A team of designers have actually been intending to Helpful resources develop a couple of shacks alongside the local recreational lake following year. When you told us that micropliling is extremely affordable, it completely caught my focus. I'll remind them to take a more detailed explore this choice so the building can be done efficiently. Steel pipelines are usually old petroleum steel piper, which had very high tensile stamina. Their dimension could range from 60mm to 300mm as well as steel quality can be as much as 550 MPa.

- Depending on the piling gear, socketing in to rock is feasible.

- In these kinds of heaps, pressure grouting is followed by tremie grouting.

- This rubbing causes a glue impact at the factors where the dirt and also pile attach.

- This process is duplicated till the dug deep into opening reaches the necessary design deepness.

- Frequently micropiles can be utilized to strengthen foundations that are compromised or of blended structure.

In buildings which have large upward pressures at the base of their columns or walls, heaps can often be an efficient foundation service. Take an instance scenario where it is suggested to build a brand-new multi storey office tower beside an existing basement parking area. High capability, limited accessibility, functional installation methods.